Chlorination is a widely used method in Effluent Treatment Plants (ETPs) to disinfect wastewater before it is discharged into the environment. This blog explores the role of chlorination in ETPs, its process, benefits, and challenges, ensuring compliance with environmental standards and protecting public health.

What is Chlorination?

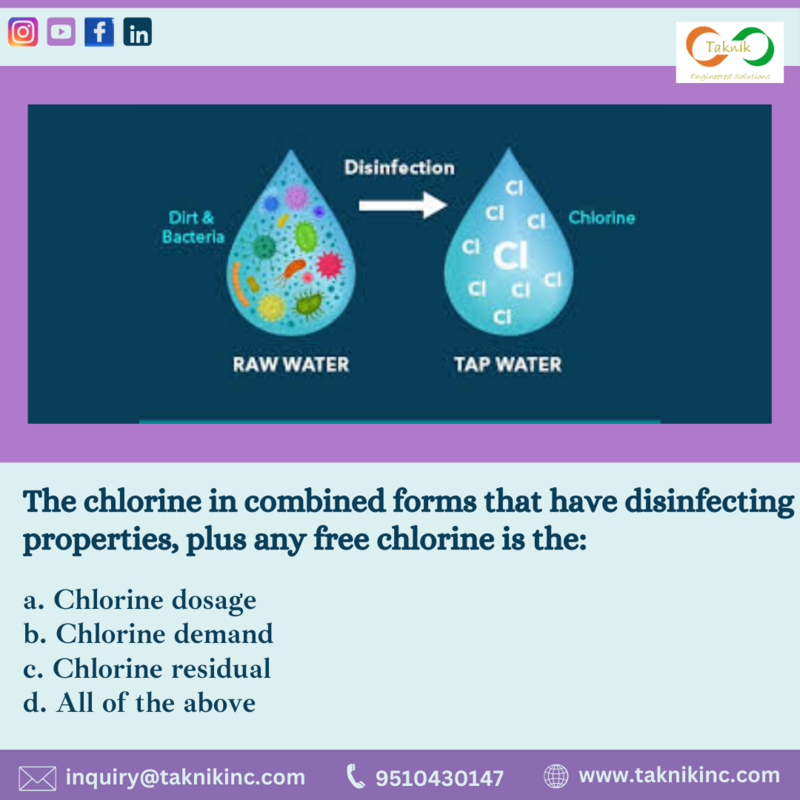

Chlorination is the process of adding chlorine or chlorine compounds to water or wastewater to eliminate harmful microorganisms, including bacteria, viruses, and parasites. This process ensures that treated water is safe for discharge or reuse, depending on regulatory requirements.

The Role of Chlorination in ETPs

Effluent Treatment Plants are designed to treat industrial and municipal wastewater. Chlorination is typically the final stage in the treatment process, aimed at achieving disinfection. It effectively reduces the biological load in treated effluent, ensuring compliance with discharge standards.

How Does Chlorination Work in ETPs?

The chlorination process in ETPs can be broken down into the following steps:

1. Pre-Treatment : Wastewater undergoes physical, chemical, and biological treatment to remove solids, oils, and organic pollutants.

2. Chlorine Dosing: Chlorine is introduced into the treated water using dosing pumps or automatic systems.

3. Residual Monitoring : Chlorine residuals are monitored to ensure adequate disinfection while minimizing excess chlorine discharge.

Types of Chlorination Methods

1. Gas Chlorination : Uses chlorine gas for disinfection. It is highly effective but requires specialized equipment and handling.

2. Liquid Chlorination: Uses sodium hypochlorite solution, commonly preferred for its ease of handling and storage.

3. Powdered Chlorination : Utilizes calcium hypochlorite powder, suitable for smaller plants or decentralized systems.

Benefits of Chlorination in ETPs

1. Effective Disinfection : Eliminates pathogens and harmful microorganisms.

2. Cost-Effective : A relatively inexpensive method for wastewater disinfection.

3. Ease of Implementation: Simple to integrate into existing treatment processes.

4. Regulatory Compliance: Ensures treated effluent meets environmental discharge standards.

5. Versatility : Can be applied to a wide range of wastewater types.

Challenges and Considerations

While chlorination is effective, there are certain challenges and factors to consider:

1. Formation of Byproducts: Chlorination can produce disinfection byproducts (DBPs) like trihalomethanes (THMs), which are potentially harmful.

2. Handling Risks : Chlorine gas is hazardous and requires careful handling and storage.

3 . Chlorine Residuals: Excess chlorine in discharged water can harm aquatic life.

4. pH Dependency : The effectiveness of chlorination depends on the pH of the wastewater.

Alternatives to Chlorination

For industries looking to reduce reliance on chlorination, alternatives like UV disinfection, ozone treatment, and advanced oxidation processes (AOP) can be considered. These methods offer effective disinfection without the formation of harmful byproducts.

Conclusion

Chlorination remains a cornerstone of wastewater disinfection in Effluent Treatment Plants due to its efficiency, affordability, and simplicity. However, it must be implemented with careful monitoring and management to address potential risks and environmental impacts. By leveraging modern dosing systems and residual monitoring technologies, industries can achieve effective wastewater treatment while adhering to environmental standards.

#taknikinc #blogger #industrialchemicals #waterchhemicals #chlorination #ETP #effluenttreatmentplant

.png)

Comments